Pan Pac – Future Proofing your Current Environment

- August 24, 2020

- Blog, Projects

- News, Ulti Roll

- 1 minute

Pan Pac has been operating for over 45 years. Growing, processing and delivering quality radiata products to international markets.

Managing 35,000 hectares of their own forest from planting through to harvesting, transport and marketing. Pan Pac’s world class sawmill, extensive kiln drying capacity and modern dry mill enables them to supply appearance and utility grade timber.

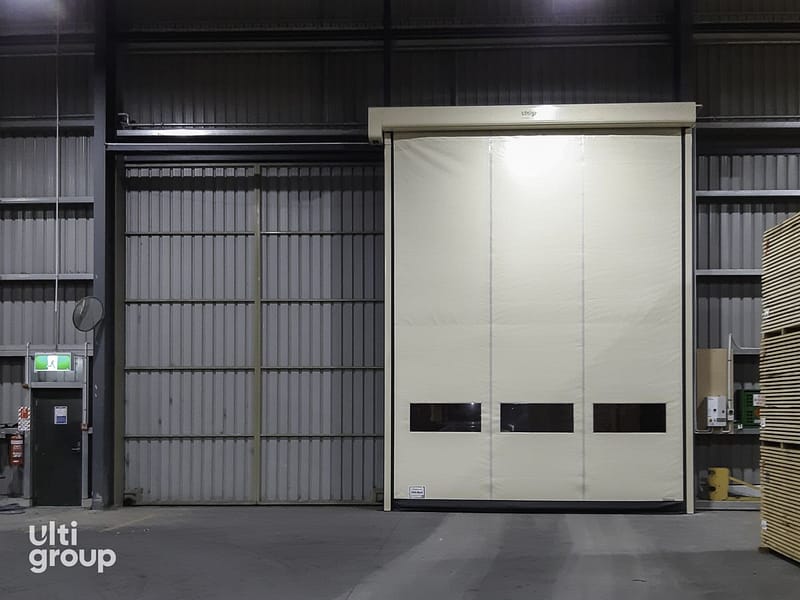

Pan Pac Alexandra recently underwent a modification to their facility. In the past Pan Pac had been operating a heavy (6000mmH x 9480mmW) metal sliding door. The full width of the opening wasn’t required for normal day to day running, so the door would be opened to halfway and would remain open during operating hours. This created issues with environmental control.

Ulti Group were able to assist Pan Pac with their requirements, creating a cost-effective solution to ensure the building remained sealed from the outside, while allowing frequent access through half of the doorway, but having the ability to still open up to full-width when required.

Ulti Group installed a specially designed Ulti Roll Plus to the opening. The Ulti Roll Plus was manufactured to half the width of the existing opening size (6000mmH x 4740mmW) and had one removable leg on a sliding rail. This was designed so that the existing sliding door could remain half open during working hours, allowing the Ulti Roll Plus to control this opening, providing the environment control they required. On the occasions when Pan Pac required the full width of the opening, the leg of the Ulti Roll Plus is detached and slid across, allowing full width access through the external sliding door.

Ulti Group is about problem solving, not selling, and future proofing your facility could be this simple.

With over 25 years in the industry, we have the knowledge and expertise to assist you through the design to install of your next project, ensuring that you are getting the solution best suited to your needs.

Contact us today to discuss your requirements.

.jpg Roll Removable Leg (1).jpg)